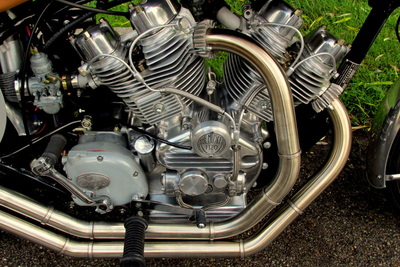

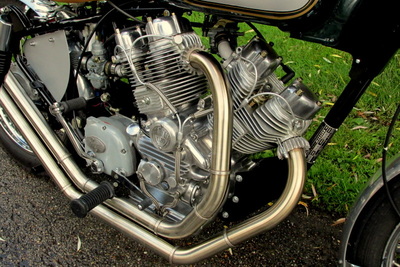

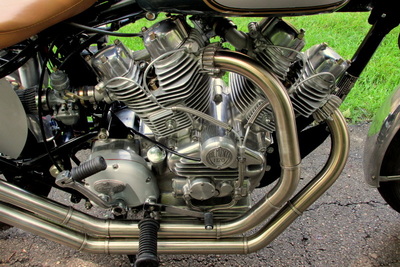

My dear friends, finally done. Can't begin to describe the complicated welter of emotions right now, a mixture of disbelief (is it really done?), relief, anxiety and total exhaustion. Hope it runs well for the new owner. Pictures were taken hurriedly on the very last day before the truck was due to arrive, thanks to continuous thunderstorms that entire week. As always happens, glitches, problems, changes till the very end. Freak wire randomly shorting out juice to front coil on the *last day*, after running perfectly during test rides in the prior two weeks! Luckily caught it before going on a wild goose chase of carb and ignition troubleshooting. To recap, this build has:

1. 1120 cc from 89mm pistons.

2. Custom "Musket" alloy cylinder barrels with cast-in tappet adjustment window.

3. Custom 7075T6 alloy conrods.

4. Heavy duty needle roller big end bearings.

5. Polished alloy mudguards.

6. Polished crankcase and timing cover.

7. 5 speed gearbox converted to right shift. This is the first build with this box.

8. Thumb-push decompressor valves on both heads allow light kick effort using the required procedure. As you know, the customer is fighting cancer and therefore is grappling with significantly lower muscle strength. To make it easier to start this big twin, the first idea tried was to lock one of the decomps "open" to remove that cylinder from compression/combustion and basically start it on just one cylinder, just like a single. Once running, release the other decomp and it would run on both. This didn't work, probably because the tiny decomp valve opening gave too much resistance to air flow and didn't allow enough flywheel momentum to develop. By accident, the procedure which turned out to work fine on the V twin is to get the *rear* cylinder decompressed on the compression stroke, close the valve and then kick firmly - now the flywheel has a full 360 + 59 degrees of rotation before it reaches tdc on compression for the *front* cylinder and this luckily allows the kickstart to get a full kick *without* compression resistance being encountered. Phew.

I can't deny that this build has been challenging in the extreme and there is a tremendous amount learned...about what not to do and how not to do it. Am taking a much needed breather while the fried brain drowsily tries to rewire itself, been a zombie for quite a while.

Heartfelt thanks to all of you for your support!

Aniket

RSS Feed

RSS Feed