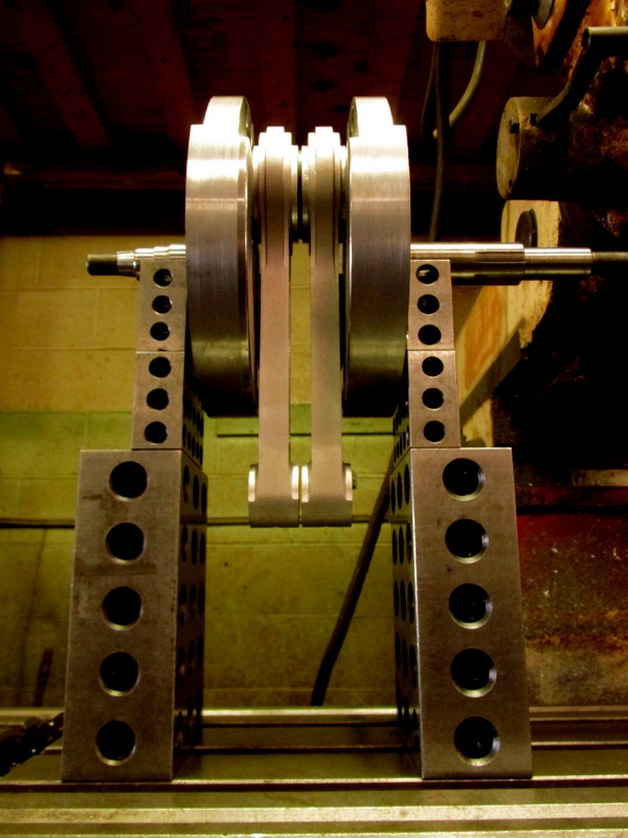

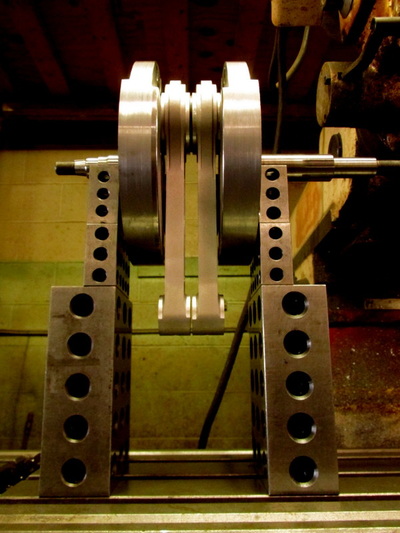

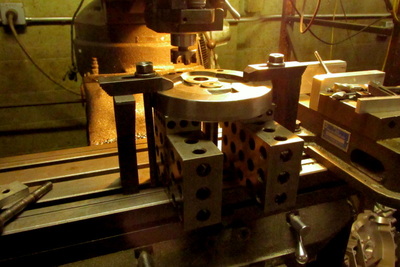

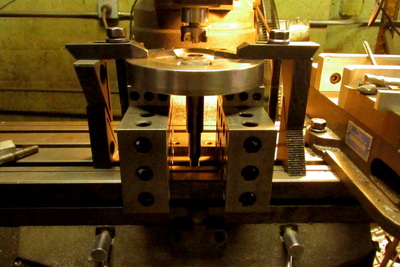

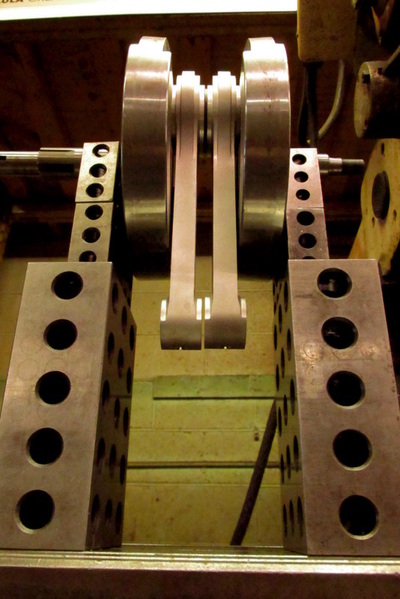

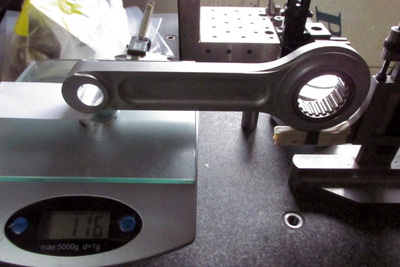

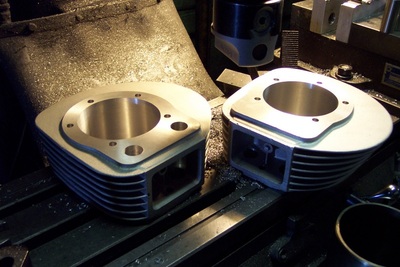

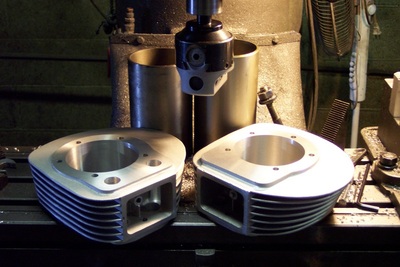

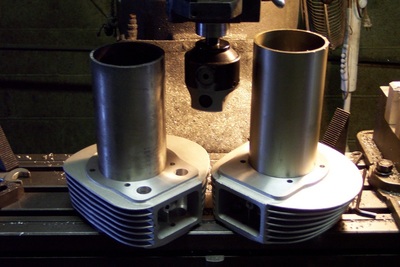

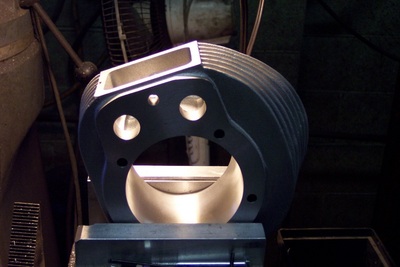

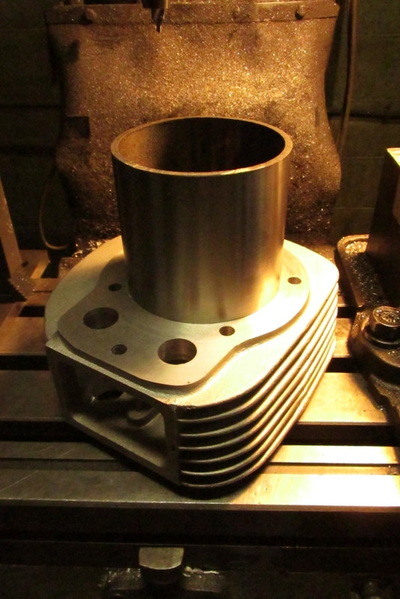

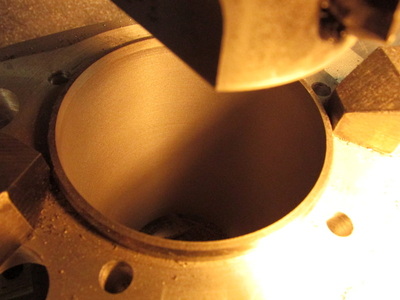

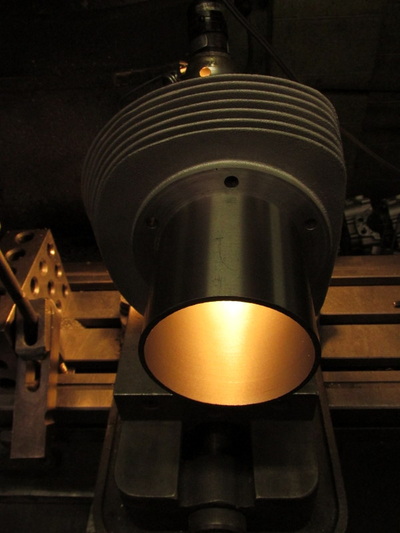

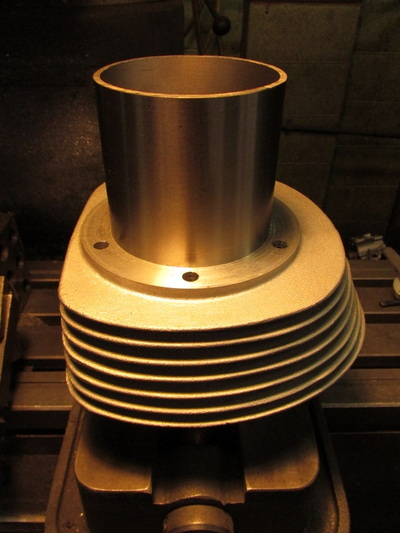

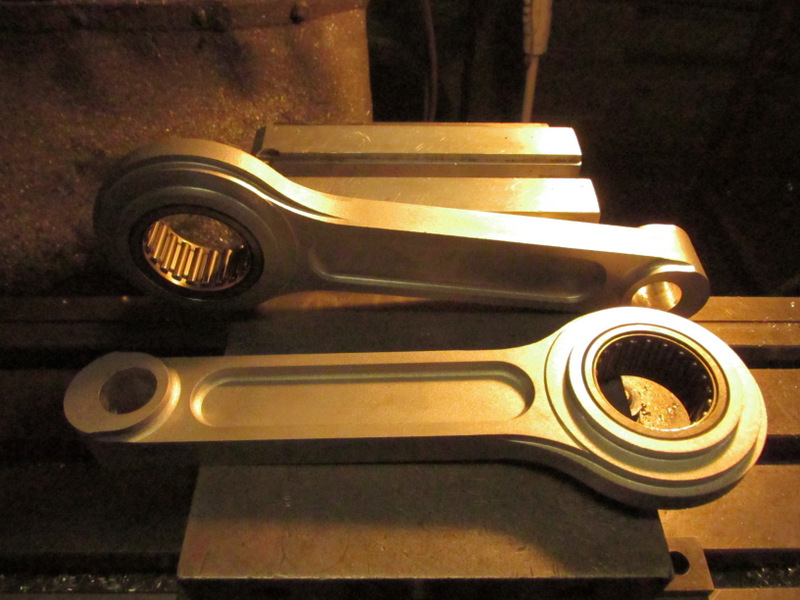

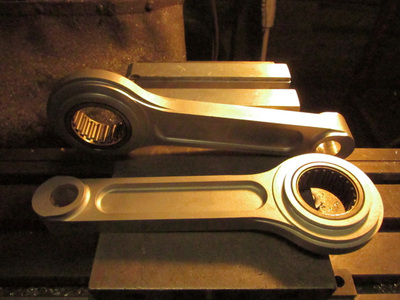

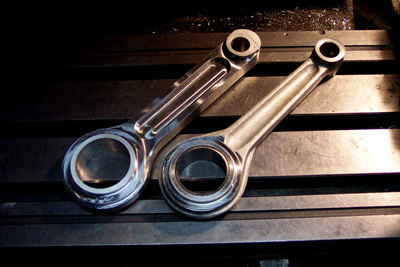

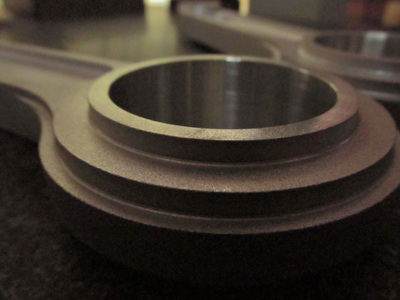

Just uploaded plenty new pics of the recent work done on the new rods, barrels and crank, you can take a look below. But, I'd like to share with you the sad side to this story.

As you know, all of these new parts are destined for the very first customer build.

A rare person indeed, now a friend more than a customer, a lifelong motorcycle enthusiast and collector.

In the initial discussions of options months ago, I mentioned to him these new products I had in mind and he immediately was on board to try them out, knowing that they would be the very first test prototypes being built. That is the spirit of the true enthusiast, willing to take the risk.

And, here is the cruel twist.

He was recently diagnosed with stage 3 cancer.

The goal is to simply get this machine done as quickly as possible and get it to him so he can ride it, enjoy it, let it hopefully be therapeutic, medicinal in some way before health issues make it hard or impossible to ride.

I can't deny that fatigue is certainly hindering the brain and body from performing to full capacity and stupid mistakes brush past, dangerously close.

Without making any melodramatic statements, all I'd like to say is that your positive thoughts, wishes, vibes will be greatly appreciated, even if unspoken.

I apologize sincerely for the overdue replies to messages, they will be addressed as soon as time is available. In the meantime, your patience is deeply appreciated.

With best wishes,

Aniket

RSS Feed

RSS Feed