I know, it has been a couple of months since the last post. If you don't hear much from me for a while, then it's quite likely due to me being buried in the workshop, nose to the grindstone, working as hard as I can.

Well, it has been a very good couple of months.

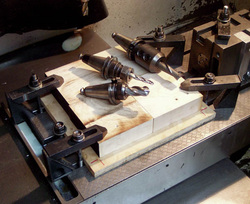

Firstly, I have been learning CNC programming and now know enough to be able to export my CAD drawings to the CAM software, process the file to output a CNC program, set up and run the machine and also tweak the programs on the fly. This allowed me to go to the workshop (where I work as a machinist) on weekends and evenings and get a good start on the new casting patterns, which are being CNC'd as opposed to the original ones which were entirely handmade. It was a quite an experience to watch the machine cut the part from glued up blocks of seasoned, kiln-dried maple in a few hours with all the geometry, fillets, radii and all, clean and precise and accurate. This would have taken days and days to do by hand. I have to say, it has given me much encouragement to reach this step. The problem with working with CAD software is that you can spend vast amounts of time creating something which basically doesn't exist. It is pixels on a screen and no matter how realistic it looks on that screen, there is a certain feeling of uncertainty and 'unrealness' about it...till you see a tangible, physical object take shape- one you can hold in your hands.

It made me wonder if I had wasted a lot of time doing things by hand before- both the wooden patterns and the machining of the castings. But I did learn a lot from the process and no doubt it is helping now.

Here's a few images from CNC test pieces-

RSS Feed

RSS Feed